To keep up with demand, Russ turns his 2 BBL system over 14 times a week! To break it down, each week they fill two large tanks with 12 BBLs of wort, along with 4 BBLs of wort in their smaller conicals. BHZ has three 4 BBL conicals for smaller batch or pilot releases and 20 BBL conicals for bigger production beers. What BHZ lacks in pure brewing capacity, they make up for in fermentation vessels. The system is your basic gas-fired three-vessel fly sparge system with a mash lauter tun (MLT), boil kettle (BK), and hot liquor tank (HLT). The coolest part is it’s basically homebrewing but on a much larger scale. The Brew Day From left to right: MLT, BK, HLT.īarrel House Z operates on a relatively small 2 BBL (barrel) brewhouse. Understanding how grains, hops, and other additions have an effect on taste, aroma, color, and mouthfeel are all critically important considerations when designing a recipe from scratch. This is where a strong background of ingredients and experience really comes into play. When designing new beers, they explore what they’re looking to brew and work backward to build a supporting ingredient profile that will ultimately help them achieve what they’re trying to produce. The entire team meets regularly to discuss strategy and share customer feedback. While Russ stresses that a brewery is about meeting customer demand and brewing what will ultimately sell, he still has the advantage of constantly brewing new beers.īHZ’s planning process always starts looking six weeks in advance. Large scale commercial brewing of the same beers over and over again can be a monotonous task that feels like the same thing day in and day out. Russ’s passion has always led him to small-batch production brewing that is everchanging. The beer bug bit Russ yet again, and BHZ was born a few years after that. Russ didn’t actually get back into brewing until several years later when Harpoon invited him back to the brewery to collaborate on the 23rd installment of their 100 Barrel Series, Rusty’s Red Rye Ale. Russ studied Fermentation Sciences at UC Davis in California, so he has a deep scientific background and fascination with the biology of beer making. If you’re thinking this is the story of another homebrewer turned commercial beer producer, you’re actually wrong. Russ eventually moved on to other ventures in 1992, but he famously designed and brewed the early iterations of Harpoon ale in his apartment in Brighton, MA! Anyway, Russ was actually the founding head brewer of Harpoon back in 1986 when they first launched.

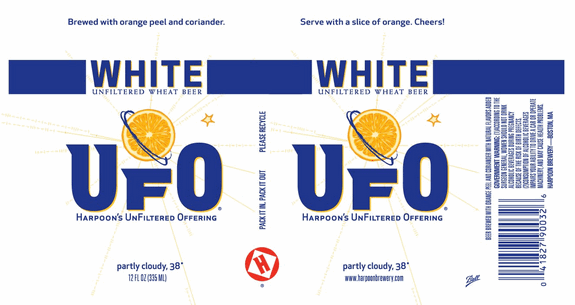

Harpoon IPA was actually the beer that got me hooked on IPAs. I’d assume most East Coast craft beer drinkers have heard of Harpoon Brewery in Boston, MA. I think I can speak for most homebrewers that learning about the commercial process first hand is on top of everyone’s wish list. As an avid homebrewer, this was a dream come true. I was lucky enough to spend a brew day with Russ and learn the ins and outs of his brewing process. You’re always going to get something new and experimental while relying on fan favorites. They’re probably one of the more diverse breweries in terms of styles in Massachusetts. This type of aging and fermenting gives their brews a unique spin and unmatched flavor profile.īarrel House Z produces an array of rotating east and west coast IPAs, flavored stouts, ales, fruited sours, wheat beers, and even craft seltzer. Everything from bourbon barrel-aged stouts to session pilsners aged in tequila barrels. Barrel House Z would become a unique brewery that grew in popularity thanks to their barrel-aged beers. The founder and California native, Russell Heissner, opened the brewery in 2015 with the idea of doing things a little differently than your typical brewhouse. Barrel House Z (BHZ) is a small-batch craft brewery located in Weymouth, Massachusetts.

0 kommentar(er)

0 kommentar(er)